Go Inside the LEE Filters Factory to See How They Handmake Their Filters and Gels

What goes into making LEE Filter's professional filters and gels?

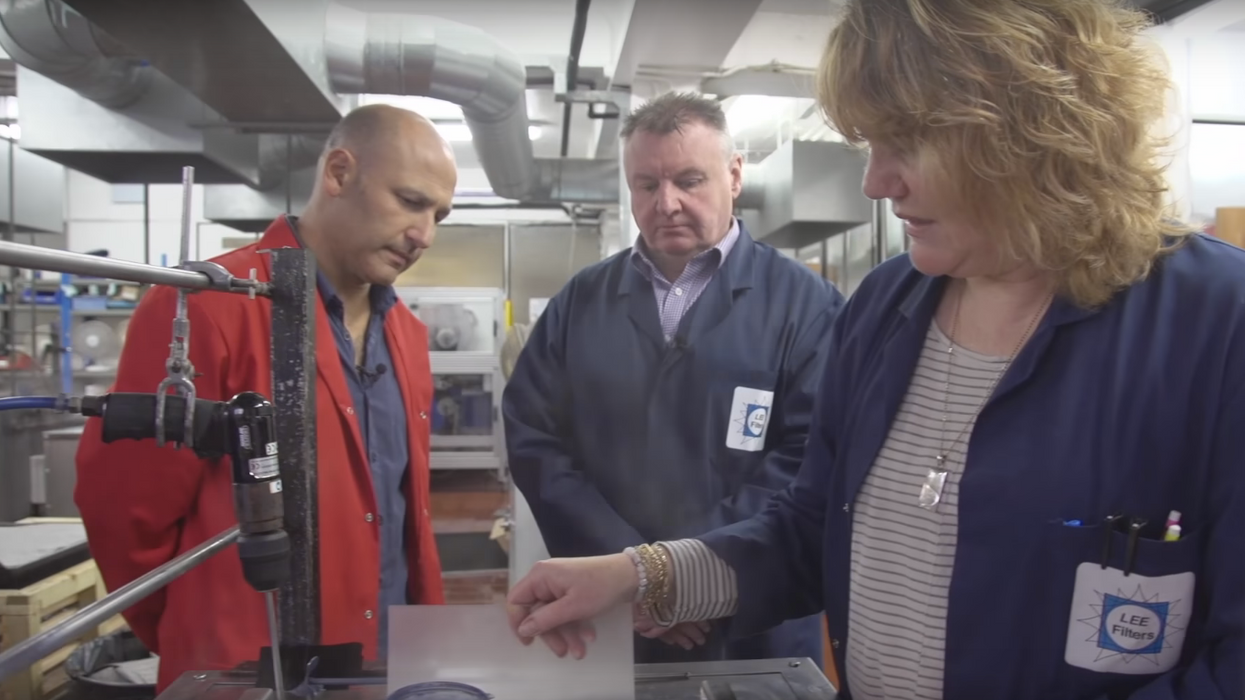

When it comes to pro-grade (or any grade) photographic and cinematic products, most of us are pretty much in the dark about how they're created before they reach the shelves. Luckily, photographer Karl Taylor got the chance to tour the LEE Filters factory to get a behind the scenes look at how their filters and gels are made, including how they go about dying every single one by hand.

LEE's filters are a popular choice among both filmmakers and photographers because of their quality, which is especially impressive since they're all hand-dyed. As you can see from the video, it takes quite a bit of finesse to dye each filter—certainly a lot more than one might imagine considering the fact that consistency is the name of the game when it comes to actually manufacturing a high volume of filters with a soft, precise gradient.

So, if you work with filters made by LEE, maybe you can appreciate them a little bit more knowing the effort and skill required to manufacture and colorize them.

Source: Karl Taylor Photography