The Future Is Here: You Can Now 3D Print Edelkrone Gear at Home

The quirky cinema support company tags in its customers to help make new products.

Edelkrone has announced Ortak, the company's new approach to manufacturing that provides customers 3D printing source files so they can 3D print products on their own.

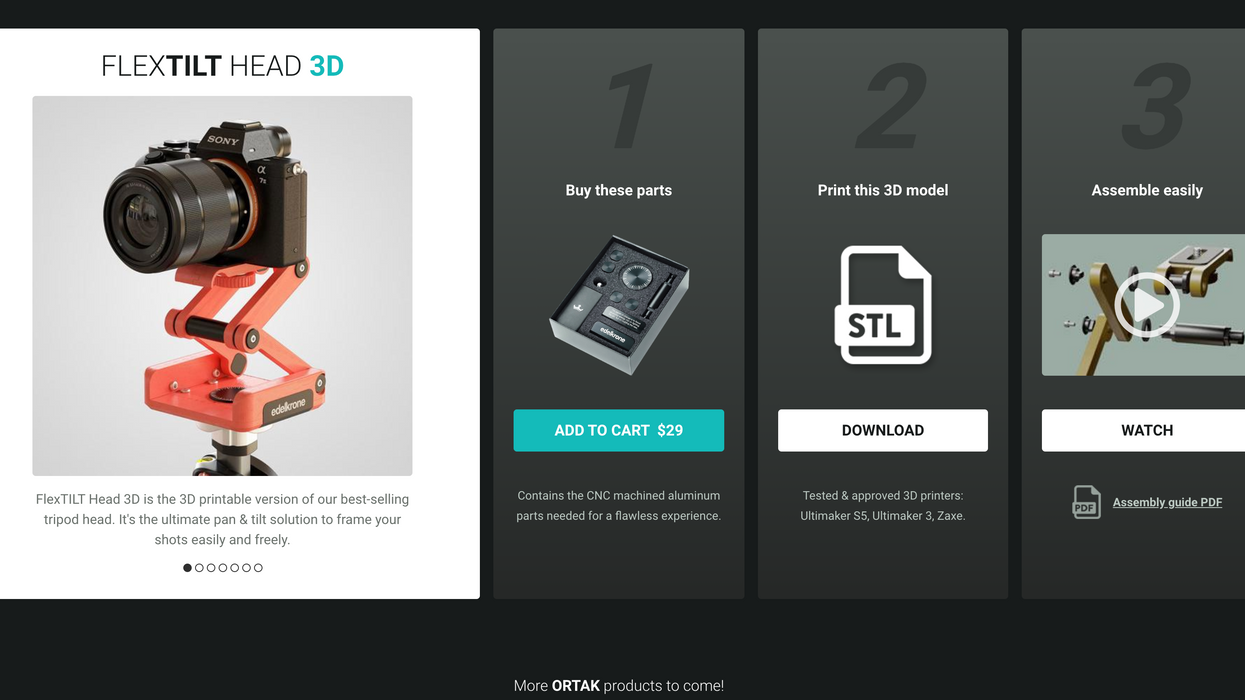

The first product on the docket is the FlexTilt Head, which is available now for $29. After the purchase of Edelkrone's bespoke CNC'ed hardware that controls the damping on the pan and tilt functions, as well as the friction locking function on both axes, the end user can then take the already available 3D-printing plans and documents and print his or her own Edelkrone product.

Edelkrone calls it "co-manufacturing."

The benefit of this idea is that it drastically cuts production costs and increases availability. My local library has a 3D printer to which I can take these plans and get myself a brand new piece of Edelkrone kit in an afternoon, all for $29 (plus that late fee I've been neglecting since 2004). Compare that to the professionally manufactured price of $149.

In a nutshell, Edelkrone manufactures all the metal bits and bobs that hold all the big pieces together, and then the customers print all of the structural pieces themselves.

There's also a wide variety of binding materials that can be used to print products on a 3D printer, much like how there are many different types of paper that can be used in a printer. Naturally, the stronger the binding material the customer uses, the stronger the Ortak-made product will be. It could be the difference between using a rigged out GH5 and an RX100 VI.

Ortak is less of a product and more of a method of manufacturing.

I've been a fan of Edelkrone's products since the SliderPLUS V1 came out years ago. I knew from the start that the clever design language that was used in its premiere product would undoubtedly transfer over to future products and the company most certainly did not disappoint.

The next few releases were equally innovative, with products like the SliderONE, the PocketRIG (which is amazing, if you don't know about it), the WING, and a slew of different variations of motion control modules, all controlled via the Edelkrone app.

The company continues to innovate and I am happy to see it continue to do so, though surely there will be plenty of growing pains to experience as more products from the Ortak lineup start popping up to experiment with.

What sort of products would you 3D print for your next shoot? Let us know in the comments.

Source: Edelkrone